Product Information

PRODUCT KNOWLEDGE

What goes into quality paving

Cape Stone strives to provide a quality paving, tiling & stone products with a professional service to our clients. This product information is to ensure you use the product to its full potential.

COLOUR

Cape Stone uses only the very highest quality imported iron oxides as colouring agents.

These colour oxides are fully mixed into our entire concrete mix and is not only a surface layer of colour.

Although the colour is guaranteed, how ever natural colours of the raw materials used in the production of our products such as sand, stone and cement does vary.

This variation will help the product to look more natural as found in natural stone and should by no means cause any concern.

The look of the product can also vary depending on the age and colour.

Bear in mind that all Cape Stone products are handmade.

A Pre Visit to the factory or showroom to come and look at the products and the colours is highly recommended.

As actual colours can vary from photo’s found on our website. Rain and sunshine may also influence the colour as well as the method of installing and sealing.

Cape Stones products age naturally like any natural stone that can be found in nature.

Although we only use the very highest quality imported iron oxides, other factors play a role in end colours achieved e.g:

- The colour of the raw materials

- Any moisture and shaded areas

- The age of the product

Because our goal is to simulate natural stone. Which by nature has different shades of colour within individual stones. There will be different shades within one colour.

Thus recommend especially with large orders that the products are mixed on site during the installation process to ensure distribution of colour throughout the installed area.

Wherever possible it is always recommended that you visit our factory and showroom to view colours before selecting our products. As actual colours can vary from photo’s found on our website.

DIMENSIONS

As all our products are handmade and thus the product is subject to production tolerances.

Our products are all specifically designed to simulate natural stone which is in essence are irregular in dimension and colour.

APPEARANCE

The product may once it is installed, show various shades of colour displays due to possible moisture in the product and moisture in the prepared sub base on which the product will be installed.

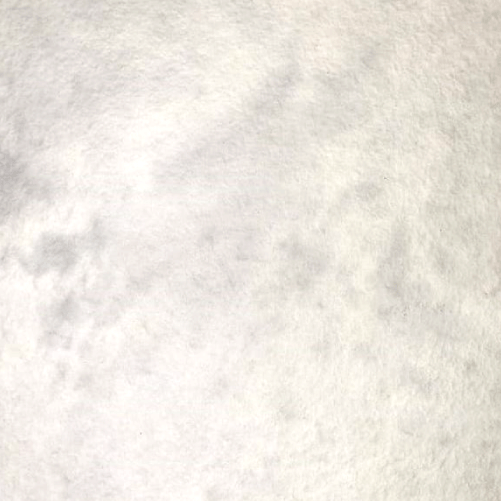

White patches or white markings may occur on the surface of the products this natural phenomenon is known as efflorescence.

This is a natural process whereby natural salts found in the raw materials used in the production of cement products gravitate to the surface of the products through the process of osmosis.

Efflorescence may lead you to think the product colour has faded or changed and will disappear in time with natural weathering and traffic.

Efflorescence is a common occurrence in high quality concrete and cement products.

LAYING OF PRODUCT

Our products are handmade and therefore variations in the thickness and dimensions of the products does occur.

You must therefore pay more attention to the installation of the product.

Although our tiles thickness are 20mm and 15mm depending on type of tile selected, sometimes more careful preparation may be required in order to get the tiles level.

The thickness of the tiles may vary from one tile to another.

At the factory there is a display for possible applications.

Any grout or cement used during the installation process of the product will stain the product if left to dry.

Cement Products like this should be kept clean during installation.

Kindly contact our office if information on product installation is required.

SEALING OF PRODUCT

The product must be clean and dry before it can be sealed.

There should be no moisture found in the prepared sub bases for paving and tiled floors before sealer is applied.

We recommend sealing to be done no earlier than two weeks after installation.

BRAKEAGES

Due to the thickness of our tile range breakages and edges chipping will occur if handled incorrectly, and should therefore be handled with extreme caution .

We expect the client to allow for 5% breakage of their tile order. The thicker 50mm and 40mm products should however not have breakages in delivery or installation process.

Kindly contact our office if information on product installation is required.

TESTING

Our products are regularly tested by PPC Cement laboratories too ensure we are keeping to our high standards.

OUR GUIDES

Professional paving knowledge

Here to help you get the most out of our product and to help you understand how to look after and install your paving and tiling products like a proffesional.

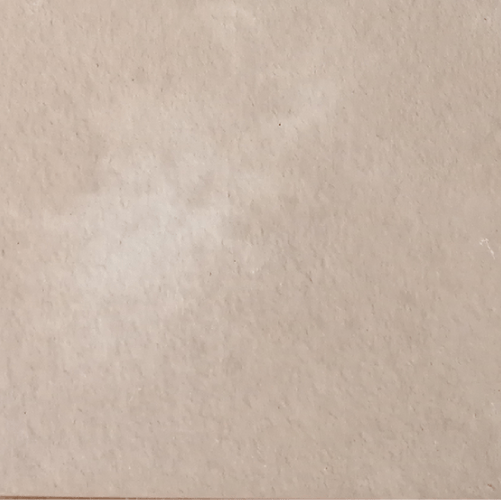

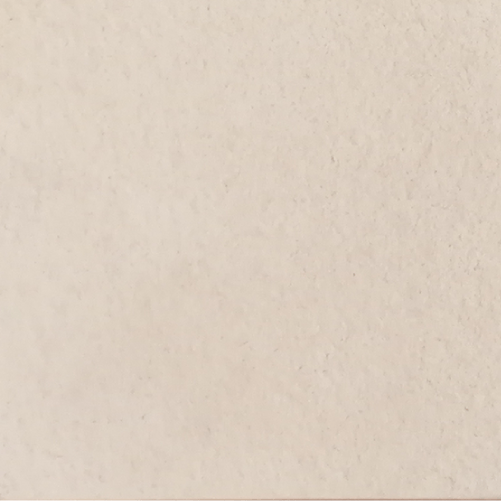

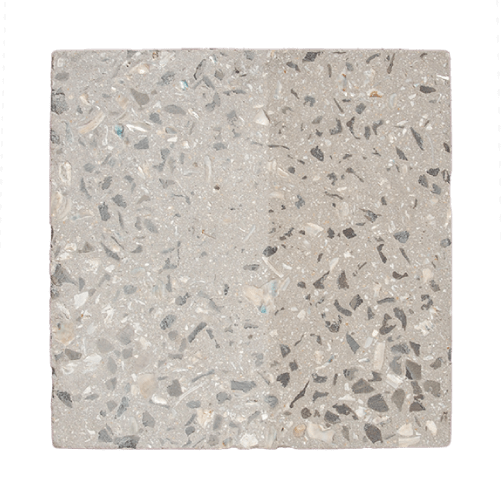

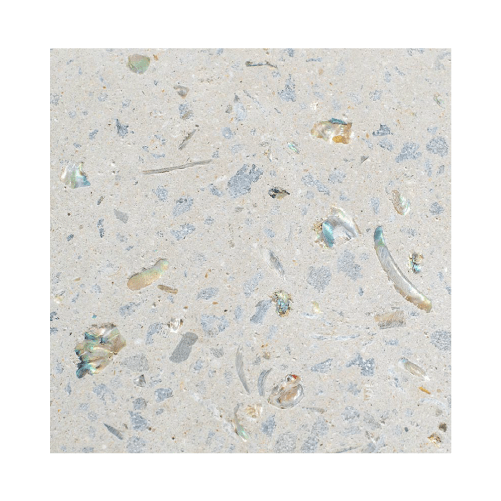

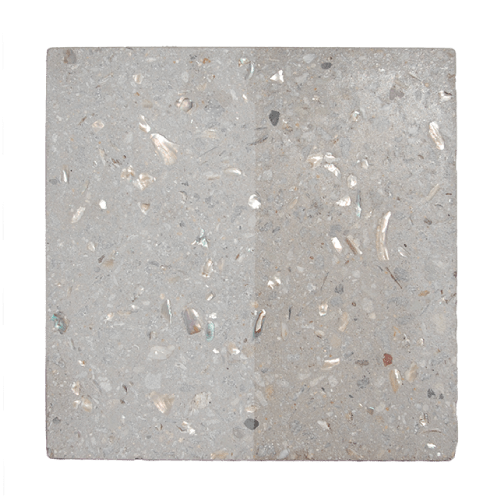

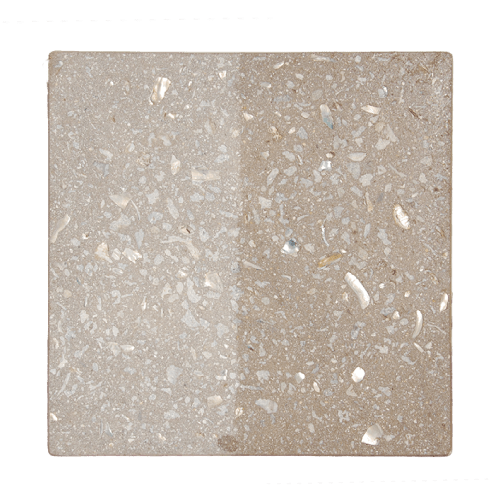

COLOUR SAMPLES

A range of colour

All our paving and tiling products are reconstructed to take on the appearance of natural stone, where shades vary and are subject to slight variations.

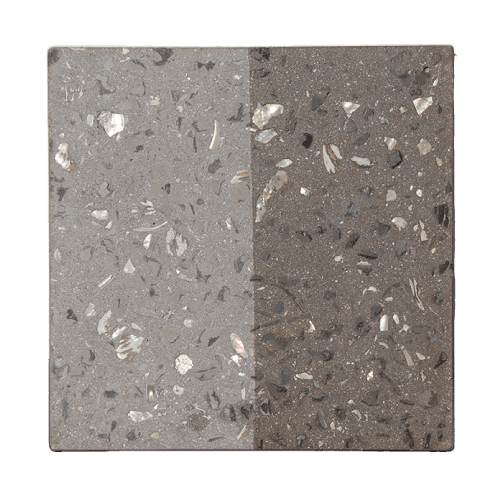

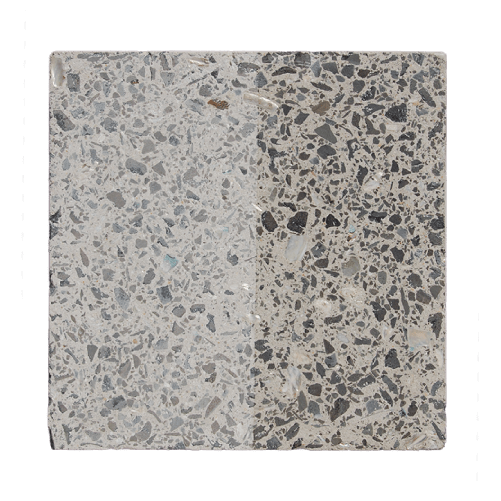

NACRE - POLISHED CONCRETE SAMPLES

Polished abalone shell

Nacre known as the mother of pearl is an organic-inorganic composite material produced by some molluscs, such as the abalone which is a creature indigenous to the Western Cape coastline, as an inner shell layer; it is also the material of which pearls are composed. It is strong, resilient, and iridescent.

EXPOSED AGGREGATE PAVING

Gorgeous with a grip

An exposed-aggregate surface is obtained by placing concrete and then stripping away the plain, minimal cement surface to reveal the natural beauty of the coarse aggregate lying beneath.